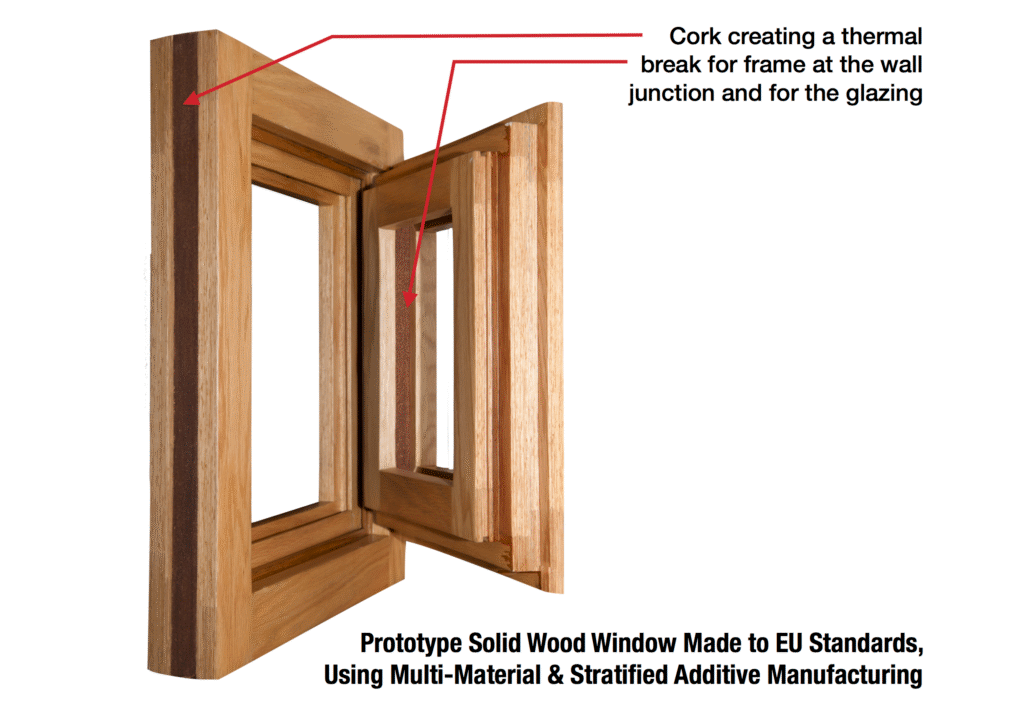

Multiple Species & Hybridization

Different species are VERY HARD to combine in conventional woodworking but they can impart special properties to the object. Our process makes it easy

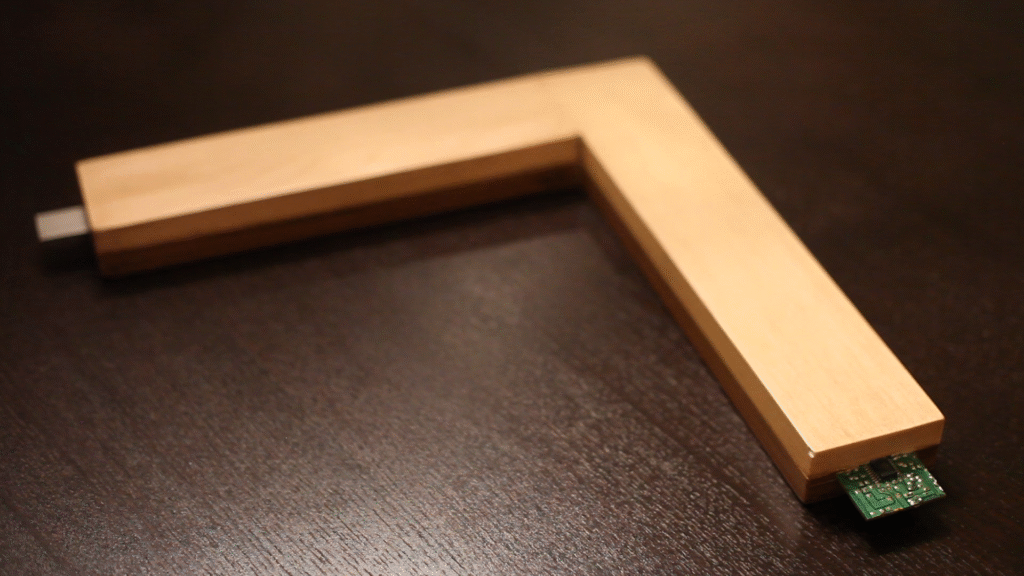

Embedding electronics “inside” wood, such as sensors, circuits, cables, re-chargeable batteries, hydraulics, and small motors is only possible [affordably & rapidly] using the SAM process. These will become pre-requisites for Smart Homes of the future

Future Windows

Follow this sequence…

- Glass uses sunlight to charge batteries

- Those batteries are located inside the frame

- Embedded cables link them to a motor in the hinges

- The motor is activated by a thermostat

- The thermostat learns from cloud-based AI

A smart thermostat monitors wind + temperature differences inside & outside a building. Then it orders windows in different parts of the building to open / shut to suit ventilation. The glass darkens / lightens. HVAC operating costs and CO2 emissions are lowered

Dream it. Make it.

A product designer* created this modular wheelchair that could adapt to changes in physical dimensions of a human being over time. The chair is also intelligent [GPS enabled] and has multi-material features

Why stop there?

Prosthetic limbs with embedded sensors, skateboards and wakeboards with GPS transmitters, composite materials in interiors of luxury aircraft and yachts (to make them lighter)… and more

There are endless applications if smart wood / hybrid wood can be made available to every industry sector

*Designed and prototyped by Pat Christie of the Daly Company