Multi-category products and mini-factories

What Does SAM Change?

Stratified Additive Manufacturing is our patented 3D process

A process which is not “subtractive”, is also a first for wood as the raw material

SAM enables hybrid properties and IoT capabilities to wood objects, adding to its relevance

The process is designed to be 100% automated – thereby making CLV building construction viable at greater speeds and at lower cost

Multiple SAM machines can be networked to establish the OD3M business model

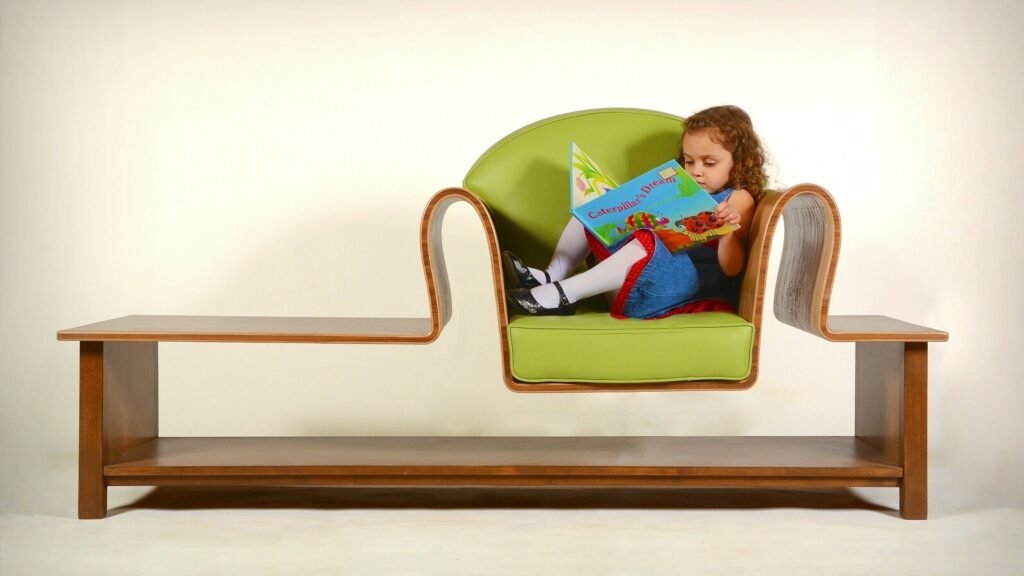

The Hollow Bench Challenge

Large Format & Complex

CONVENTIONAL WOOD: Producing this bench via conventional woodworking is too complicated. Making one single piece is hugely expensive. Changing species of wood for each order is a nightmare

3D PRINTING: 3D Printing with wood-resin filament is not affordable for such a large format. It would take several days to print and would not be aesthetic. The bench would snap like a toothpick

SAM is a simple, affordable, durable, flexible and speedy solution

Small and [More] Complex

The Sushi Tray Challenge

Traditional processes: This apparently simple object cannot be made by any single machine. It would need: 1) A Saw 2) Moulder 3) Borer 4) Planer and above all, 5) a skilled craftsman to assemble it

SAM process is designed for a single, super flexible machine with precision of 0.1mm , to do all that, directly from a designer’s CAD file

Kintsugi

The philosophy of our process is in the same vein as the age-old Japanese craft of Kintsugi

Wood has valuable structural and visual characteristics. We keep those attributes intact as we take this sustainable material from trees and put it back together as complete objects

Like gold lacquer which strengthens and adds value to broken ceramics in Kintsugi, SAM uniquely augments and adds new properties to wood objects

Our process is industrial in nature but craftsman-like in capability. It maintains respect for the material while still making it more relevant and purposeful